Durable materials often face a myriad of chemical exposures in their service life. To ensure the longevity and functionality of these materials, rigorous chemical resistance testing protocols are essential. These protocols comprise subjecting materials to various corrosive agents under controlled conditions, observing their response over time. The results of these tests furnish invaluable data on the material's susceptibility to degradation, allowing for informed procurement and design considerations.

A standardized testing protocol frequently includes a range of parameters such as ambient conditions, concentration of the chemical agent, period, and evaluation criteria.

The selection of specific test methods and bio based yarn agents is determined by the intended application of the material and the anticipated service conditions it will experience.

Additionally, these protocols may incorporate accelerated testing methods to simulate long-term exposure and deliver a more rapid assessment of material durability. By adhering to well-established testing protocols, engineers and manufacturers can reduce the risk of degradation in durable materials, ensuring their reliability over time.

Evaluating Barrier Properties in Harsh Chemical Environments

Assessing the efficacy of barrier materials under extreme chemical exposures is critical for ensuring product integrity and operational safety. These environments often involve aggressive substances that can attenuate barrier properties over time.

- A comprehensive evaluation must consider a variety of metrics, such as permeation rates, tensile strength, and chemical resistance.

- Specialized test methodologies are often necessary to accurately simulate the challenges encountered in these environments.

- Data from these tests can then be employed to identify the most suitable barrier materials for a given application, minimizing potential compromise.

The Impact of Severe Chemical Exposures on Durability: A Comparative Analysis

This study delves into the efficacy of diverse materials under extreme chemical exposure. We aim to determine the relative durability of these materials when subjected to a range of toxic substances. Through systematic testing protocols, we will investigate the effects of chemical exposure on various material properties such as compressive strength. The results of this study will provide valuable insights for engineers and researchers in selecting appropriate materials for applications requiring exceptional resistance to degradation.

Understanding Resistance in Chemical Protections

Chemical barriers serve as a critical line of defense against invading pathogens. These barriers utilize a wide range of chemicals to impede pathogen growth and invasion. However, pathogens have evolved sophisticated strategies to circumvent the effectiveness of chemical barriers. Understanding these resistance mechanisms is essential for developing effective countermeasures against infectious diseases.

- One common strategy involves pathogen-produced enzymes that can break down the active components of chemical barriers. For example, some bacteria produce enzymes that destroy the antimicrobial peptides found in skin secretions.

- Another approach is the modification of pathogen structures to reduce their vulnerability to chemical barriers. This can involve the production of a coating that prevents the penetration of antimicrobial substances.

- Moreover, pathogens can develop immunity to specific chemical barriers through genetic mutations. These mutations can alter the target site or role of the molecule, rendering it ineffective against the pathogen.

Assessing the Long-Term Durability in Chemical-Resistant Coatings

Determining the long-term durability of chemical-resistant coatings is the crucial aspect for selecting the appropriate protection from various industrial applications. They coatings are designed to withstand exposure to aggressive chemicals, minimizing corrosion and degradation during extended periods.

Various factors affect the durability of chemical-resistant coatings, including the specific composition in the coating, the environmental conditions, and the nature for the chemicals being.

- Rigorous testing protocols are to evaluate the long-term performance of coatings under intended conditions.

- Testing methods often involve exposing coatings to a range at chemical agents over extended periods, measuring any signs of degradation or failure.

- Additionally, factors such as temperature fluctuations, UV radiation, and mechanical stress can also influence the durability of coatings.

As a result, manufacturers develop coatings who provide optimized properties for withstand the specific challenges of their intended applications.

Developing Novel Materials with Enhanced Chemical Resistance and Barrier Performance

The field of materials science is constantly pushing the boundaries, seeking to develop novel materials with improved properties. One area of particular interest is the development of materials that exhibit enhanced chemical resistance and barrier performance. This is driven by a growing demand for materials capable of withstanding harsh environments and preventing the permeation of undesirable substances.

These advanced materials find broad applications in diverse industries, including aerospace, automotive, electronics, and packaging. For example, in the aerospace industry, high-strength materials are crucial for reducing aircraft weight and improving fuel efficiency. In the automotive sector, chemical resistance is paramount for components exposed to corrosive fluids and harsh weather conditions. Furthermore, in electronics, barrier materials play a vital role in protecting sensitive circuitry from moisture and contaminants.

To achieve these enhanced properties, researchers are exploring innovative synthesis techniques, material compositions, and processing methods. This includes the use of nanomaterials, composites, and coatings to create materials with tailored properties. The development of novel analysis techniques is also essential for evaluating and understanding the performance of these advanced materials.

As research progresses, we can expect to see a continuum of new materials with superior chemical resistance and barrier performance, driving advancements in various technological fields.

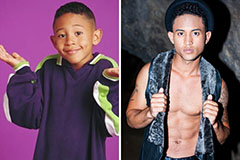

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!